Fabrication Events

Scaling from chaos to confidence with one system that keeps 60,000+ items moving.

54

employees coordinating seamlessly across operations

1,100

projects managed annually without adding headcount

60,000+

inventory items tracked in real time

When Paul Hines founded Fabrication Events in Frederick, Maryland in 2000, he had a clear vision: deliver flawless event experiences through meticulous attention to detail. Twenty-five years later, that commitment has grown into a 54-person operation managing 1,100 projects annually from their Jessup warehouse, serving premier venues throughout Maryland, Virginia, and Washington, DC.

The company specializes in drape, dance floors, stages, and specialty furniture — the kinds of rentals that transform spaces. But as their reputation grew and their inventory expanded to over 60,000 items, the systems that worked for a smaller operation started breaking down. Paper pull sheets meant double-entry work. Manual scheduling meant playing telephone between departments. Without real-time inventory tracking across dozens of simultaneous events, conflicts were inevitable.

The wake-up call came when Paul calculated what mistakes were costing. “If a job gets pulled and somebody adds something after a written sheet has gone out, that job goes and no one ever sees that they were added,” Paul explains. “Now we have to refund that money or we’re stuck scrambling last minute.”

But it wasn’t just about preventing losses — it was about sustainable growth. “[Without Goodshuffle Pro], we couldn’t grow the way we do without significantly increasing our staff,” Paul says. “The amount of time and effort that training takes would dramatically limit the speed at which we can grow.”

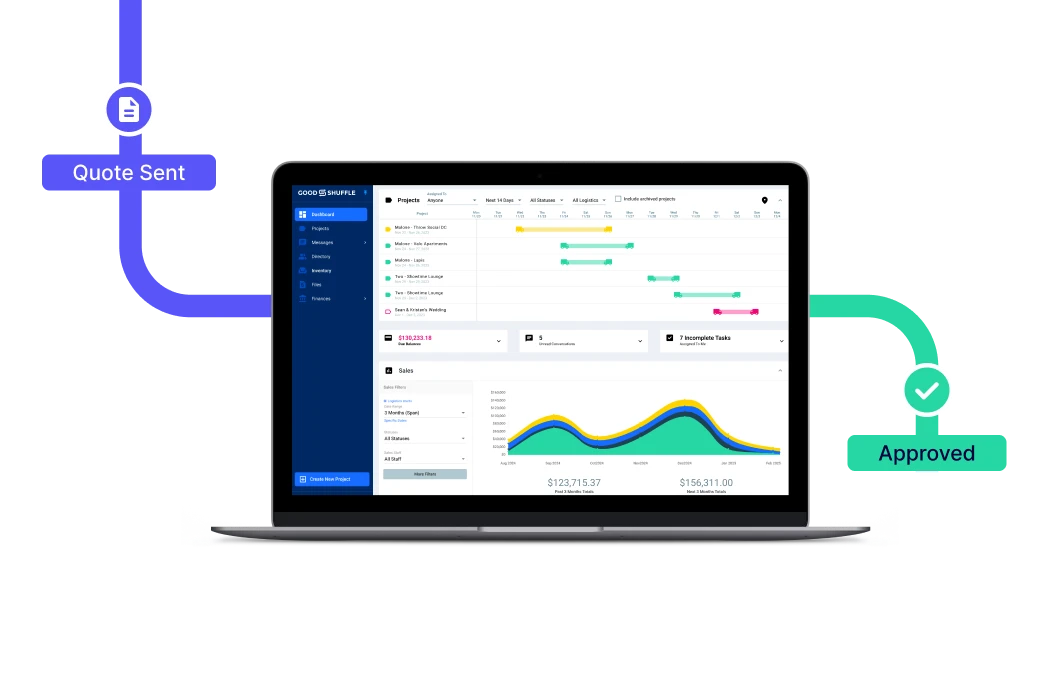

One System Gives the Full Team Visibility

Goodshuffle Pro gave Fabrication Events what they needed most: one system where everything lives. The operations team transitioned entirely to digital pull sheets on tablets. Now, as warehouse staff scan and pull items in real time, everyone associated with the project can see exactly where things stand.

“Having all the inventory in one place synced with the whole sales process, and then them seeing a live version of it on their tablets for the load list, really helps everyone be confident that we have all the items correctly,” says Phil Hill, Director of Sales.

The visibility matters especially at 3:00 AM. “Somebody getting ready to come in can pull it up and see: has my truck already been loaded for a 4:00 AM departure?” Paul explains. “They don’t have to worry about calling somebody in the middle of the night or arriving and not knowing what’s going on.”

Last-Minute Adjustments Aren’t a Headache Anymore

Dispatch has been a game-changer during busy seasons, when Fabrication Events might have 10-14 events happening simultaneously. “When an installation has to move back five hours, you can see conflicts with vehicles and crew members assigned to other jobs in real time,” Paul says. “That extra hour or two it buys you enables you to better cope with the situation.”

Before Goodshuffle Pro, last-minute changes meant frantic phone calls and crossed wires. Now updates happen instantly. “We’re not having to have a salesperson call dispatch, and then the dispatcher call the driver and crew and everyone else, hoping we get in touch with everybody,” Paul notes.

For Angelica Ruiz in warehouse operations, having barcoding integrated with Goodshuffle Pro transformed inventory management. “When we have an item that’s missing, we’re able to see through the barcode system which job it came from,” she explains. “We’re able to contact the venue or the client and retrieve it.” Being able to pinpoint exactly where items went means they return to inventory rather than being written off as lost.

The Math That Matters

When Paul evaluates technology investments, he looks at the full picture: payroll, training, reputation, and culture. “One person, even at minimum wage for a year, is going to cost you more money than adding 15 or 20 Goodshuffle seats,” he explains.

More importantly, scaling without proportionally increasing headcount means sustainable growth. “Being able to scale up in what we do without having to bring in a ton of new people that need training and have a learning curve is very beneficial,” Paul says.

His advice for companies facing the same decision? “If what you’re using isn’t working — which it’s probably not if you’re asking yourself that question — then it’s time to move,” Paul says. “If you’re asking that question, if you’re having those problems, you’re already behind the eight ball.”

For smaller companies hesitant to invest, Paul’s message is: “You need to plan for growth. If you think you’re going to be a successful company, you need to build an infrastructure that can scale with you. Because if you’re doing well, you’re going to be short-staffed, and the last thing you have time for is rebuilding a system.”

Goodshuffle Pro has given Fabrication Events confidence. “We can have 54 employees working on 1,100 projects a year, managing over 60,000 inventory items from anywhere, and feel confident that internally, everything is in place,” Paul says. “That allows us to focus on clients and sales and growth.”

More Customer Stories

Bristow Party Rentals

Family-owned party rental business improves sales by 71% in 3 months.

Get Started With Goodshuffle Pro

1,000+ event companies run their business on our software. Book a demo to see the product in action, then set up your account.